- No products in the cart.

Warehouse Racking System: Types, Load Capacities & Buying Guide (UK)

10

Feb

If you’re looking for a warehouse racking system, you’re probably at a point where space is tight, stock is growing, or your current setup just isn’t working anymore.

Most UK warehouses don’t fail because they lack space, they fail because their storage isn’t planned properly. The right racking system can transform how your warehouse runs day to day. The wrong one quietly slows everything down.

This guide is written for people who want clarity before buying: what type of racking makes sense, how load capacity actually works, and how to choose a system that fits your operation today and still works two years from now.

What Is a Warehouse Racking System and Why Does It Matter

A warehouse racking system is a heavy-duty steel structure designed to store goods vertically and safely, usually palletised or boxed stock. Unlike light shelving, racking is built to handle repeated loading, mechanical handling, and industrial weight.

In practical terms, good racking helps you:

1.) Store more without expanding your footprint

2.) Keep aisles clear and predictable

3.) Reduce handling time and stock damage

4.) Create a safer working environment

This is why most professional warehouses use racking as their backbone, not an afterthought.

Durability and Safety: What UK Buyers Should Expect

One thing that does matter and often gets glossed over - is durability.

Warehouse racking isn’t decorative. It needs to hold up to daily use, heavy loads, and occasional knocks without shifting or degrading. In the UK, that also means:

Clear load ratings

Stable installation on suitable floors

Consistent performance over time

A strong racking system doesn’t just organise stock; it improves workflow and reduces risk. That’s why buying well-specified systems from the start saves money in the long run.

The Most Common Warehouse Racking Types (Explained Simply)

1.) Selective Pallet Racking

This is the most widely used warehouse racking system in the UK. Pallets rest on horizontal beams, and every pallet is accessible.

Best suited for

1. Mixed SKUs

2. Fast-moving stock

3. Warehouses that value flexibility

A tall, modular unit like a Racking Storage Unit – 3000 × 2100 × 600 is ideal when you want to make full use of vertical space while keeping access straightforward.

2.) High-Density Racking (When Floor Space Is Limited)

High-density systems reduce aisle space to increase storage volume.

Best for

1. Bulk quantities of the same product

2. Warehouses with predictable stock rotation

The trade-off is access. These systems work well in the right conditions, but they’re not a universal solution.

When Warehouse Shelving Is the Better Choice

Not every storage area needs pallet racking.

If your stock is:

1. Hand-picked

2. Smaller or varied

3. Frequently accessed

Then warehouse shelving often makes more sense.

Lower-height options such as a Racking Storage Unit – 2000 × 2100 × 600 are commonly used in parts stores, workshops, and back-of-house areas where strength still matters but forklifts aren’t involved.

3) Longspan Racking

Longspan racking is a heavy-duty shelving system designed for hand-loaded goods, cartons, and bulk items that don’t require pallets.

Best suited for

1. Picking areas

2. Back-of-house storage

3. Workshops and spare-parts storage

Longspan racking provides high load capacity per shelf while remaining easy to adjust. Many warehouses use longspan racking alongside pallet racking to handle different types of stock efficiently.

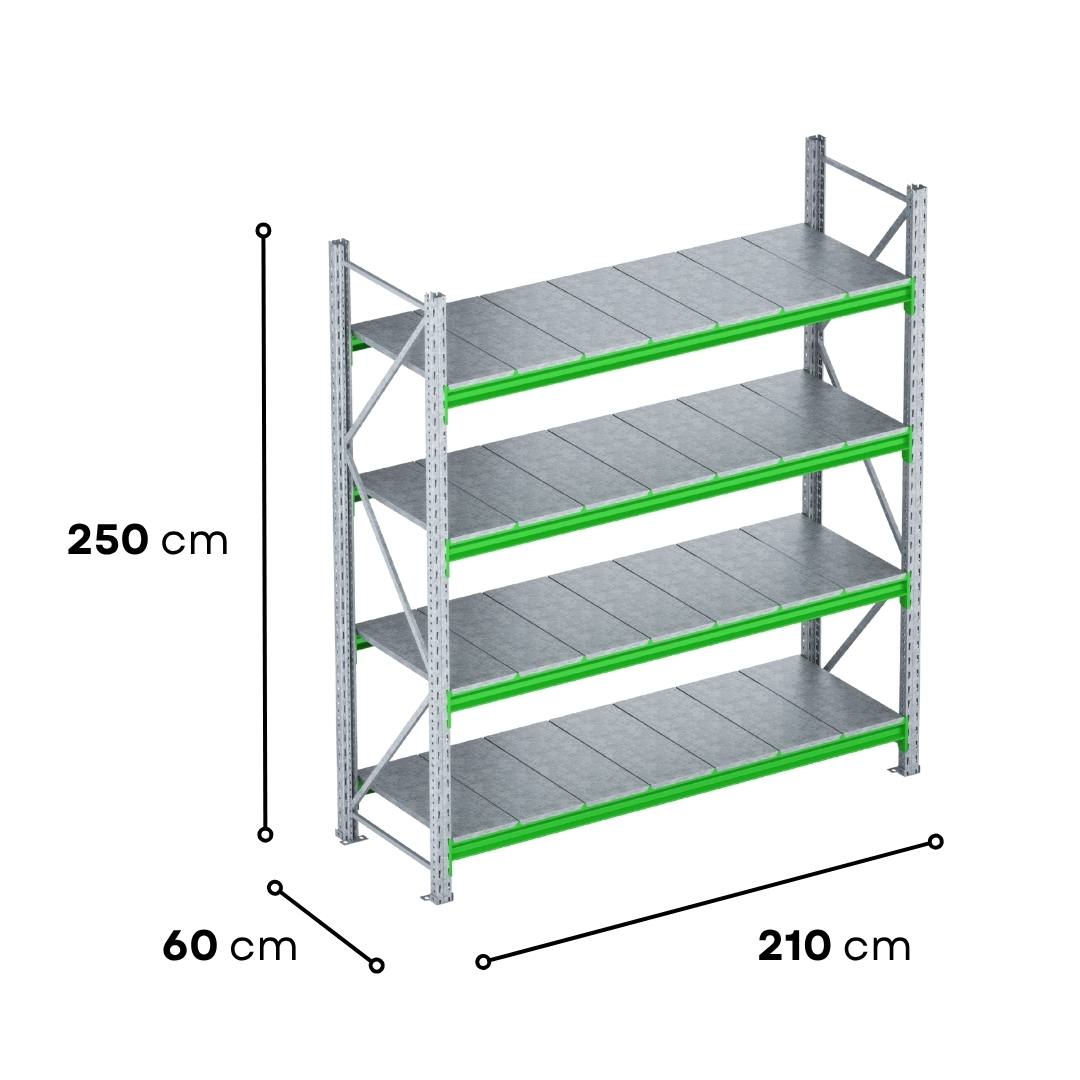

Racking Storage Unit – 2500 × 2100 × 600

This is the best “sweet spot” option for most UK warehouses: high capacity, good height, easy access.

4) Shelving Accessories and Expansion Components

A key advantage of modern racking systems is modularity. Dynamic Shelf supplies shelf sets and components that allow your storage to grow with your business.

Why this matters

1. Add extra levels without replacing entire bays

2. Adjust shelf heights as stock changes

3. Extend existing systems cost-effectively

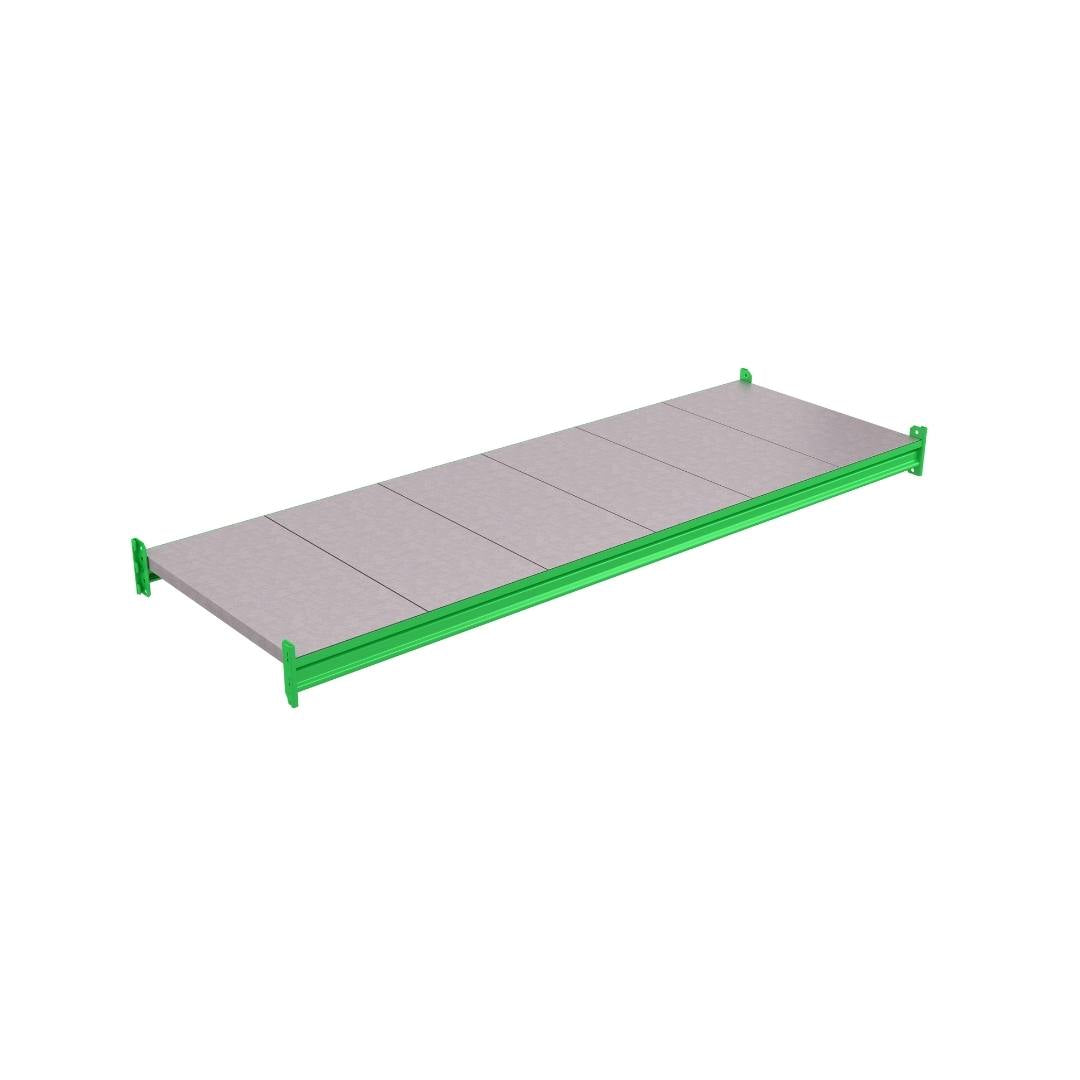

Racking Shelf Sets (1200 × 600)

Additional shelves and compatible components for expansion

This approach supports long-term planning and avoids unnecessary reinvestment.

Many UK warehouses use a combination of racking and shelving to balance bulk storage with efficient picking.

Height isn't just about your ceiling

Choosing racking height isn’t just about how tall your building is.

You also need to consider:

1. Forklift reach

2. Safe loading and unloading

3. Fire and lighting requirements

4. Ease of maintenance

For many UK operations, a mid-height option like the Racking Storage Unit – 2500 × 2100 × 600 offers the best balance between capacity and practicality.

Build for change, not just now

One of the strongest advantages of modern racking systems is modularity.

A good racking storage system should allow you to:

1. Adjust shelf heights

2. Add extra levels

3. Extend bays as stock grows

That flexibility is especially valuable for growing UK businesses.

Common Warehouse Racking Mistakes and How to Avoid Them

These are issues we see repeatedly:

1. Underestimating load weights

2. Buying based on price instead of specification

3. Forgetting aisle width and handling space

4. Choosing height without checking equipment reach

5. Not planning for future expansion

Most of these mistakes don’t show up immediately — they show up months later, when efficiency drops or changes become expensive.

Pick Something that Lasts

Good racking should just work. It should make stock easier to handle, space easier to use, and growth easier to plan for.

Before you buy, spend time understanding your actual load requirements, match the system to how you really operate day-to-day, and go for durability and flexibility over bargains.

Racking isn't just storage. It's the backbone of how your warehouse functions.